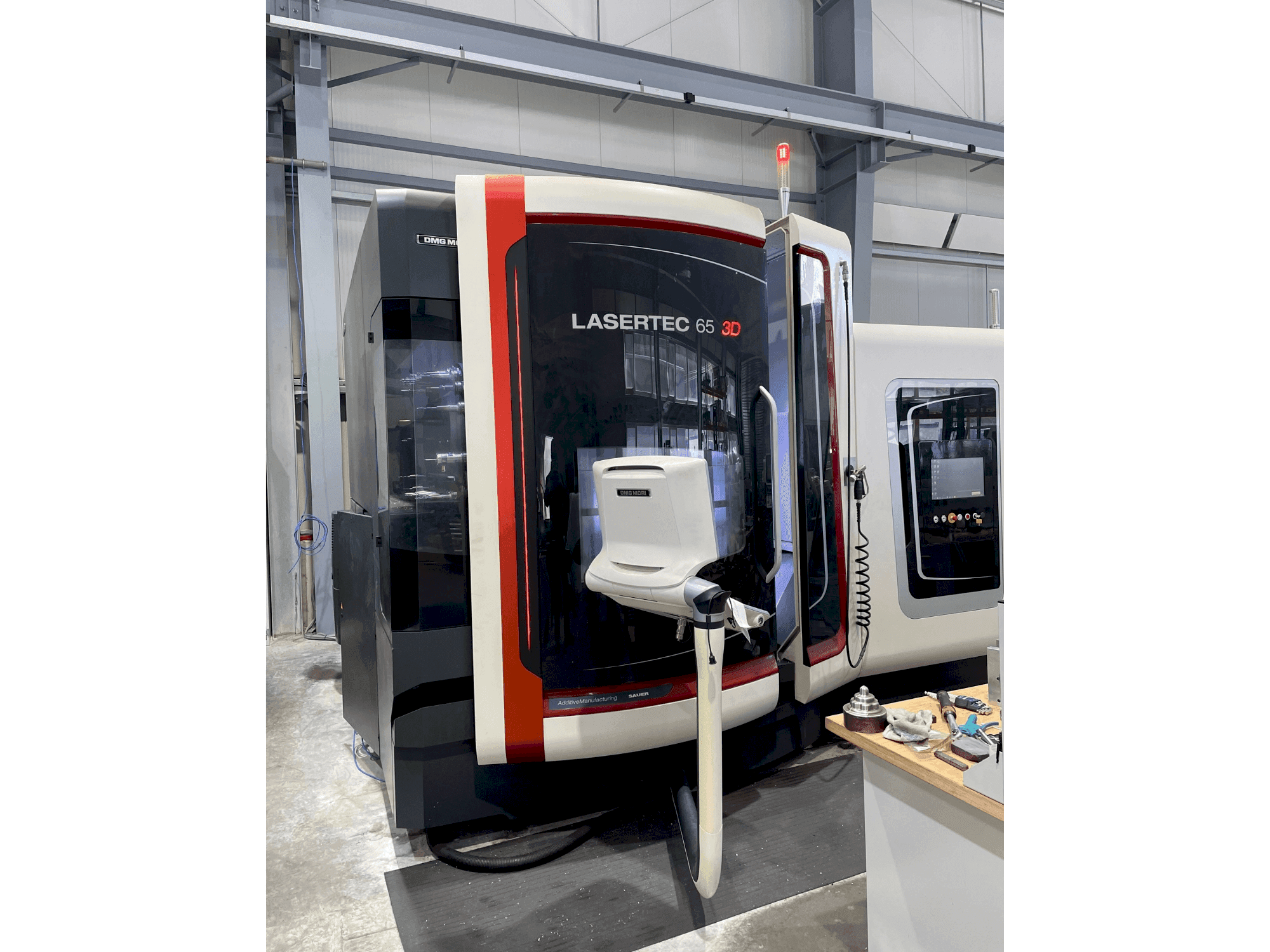

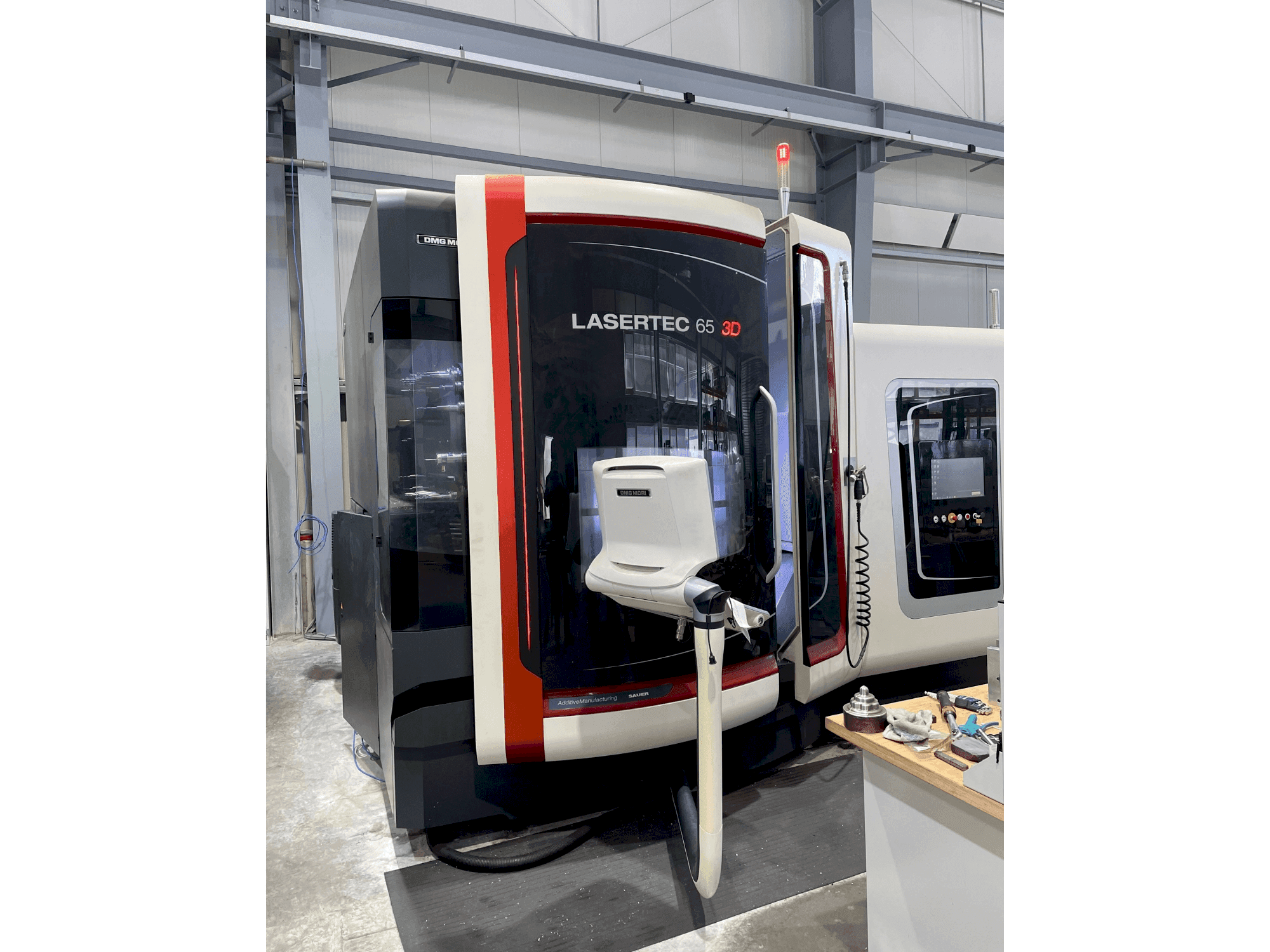

DMG MORI - LASERTEC 65 3D HybridAT-MIL-DMG-2014-00001

Haben Sie weitere Fragen? Kontaktieren Sie uns!

Philipp Gubisch

+49 162 402 75 81

p.gubisch@gindumac.com

- GINDUMAC

- Produkte

- Werkzeugmaschinen

- DMG MORI LASERTEC 65 3D Hybrid 5-axis precision machine for milling and laser machining

This DMG MORI LASERTEC 65 3D Hybrid 5-axis precision machine for milling and laser machining was manufactured in the year 2014 in Germany. It is special for the ability to produce components using 3D Printing and to post-process them at the same time. Ideal for manufacturers who need a high-performance additive manufacturing solution of metallic 3D components. The machine features a fixed integration of the laser head in the headstock for greater installation space and more performance. In addition it offers 5-axis material application via coaxial nozzle for uniform powder distribution regardless of the laser build-up direction. It is the ideal dedicated solution for prototypes, small series, repair and coating. This LASERTEC 65 3D is equipped with an integrated SK 40 motor spindle with spindle speed up to 14,000 1/min. In addition it operates with a fiber-guided diode laser of 2.5 kW laser power. Next to internal coolant supply (IKZ) it comes with Renishaw measuring probe and Blum tool measurement option. Furthermore it is appreciated for its generously sized work area that is easily accessible, along with travel dimensions of 650 × 650 × 560 mm (X / Y / Z). It is a supremely adaptable 5-axis machine suitable for a wide array of laser and milling tasks, delivering consistently high-quality results without compromise.

Übersicht

- Hersteller: DMG MORI

- jahr: 2014

- MODELL: LASERTEC 65 3D Hybrid

- Produktionsstunden: 1520

- anwendungstyp: Fräsen

- Standort: Österreich

- maschinentyp: Universal-Bearbeitungszentrum

Technische Daten - DMG MORI LASERTEC 65 3D Hybrid

Maße

- Maschinentiefe: 1050 mm

- Maschinenhöhe: 2000 mm

- Tischlänge: 800 mm

- Tischbreite: 650 mm

Bewegung

- Anzahl der Achsen: 5

- X-Achsverfahrweg: 650 mm

- Y-Achsverfahrweg: 650 mm

- Z-Achsverfahrweg: 560 mm

Technische Spezifikation

- Anzahl der Werkzeuge: 60

- Spindelleistung: 14 kW

- Spindeldrehzahl: 14000 RPM

- Kühlmittelzufuhr durch die Spindel: Ja

Zusätzliche Informationen

Additional equipment

- Inner cooling system 40 bar, 23 l/min

- Scraper belt chip conveyor with coolant system 600 liters, paper belt filter

- Infrared measuring probe Renishaw OMP 60 Version for SK 40 (the probe is automatically inserted into the work spindle from the tool magazine)

- Rinsing gun with pump 2 bar/40 l/min

- Oil/emulsion mist separator

- Tool measurement in the Blum Laser work area

- MPC Machine Protection Control & 3D quickSET

- Surcharge for powder feeder Twin System

- Suction unit with secondary filter stage

- electronic handwheel Siemens 840D

*Es kann zu Abweichungen zwischen den angegebenen Daten und den tatsächlichen Werten kommen, diese müssen vom Vertriebsmitarbeiter bestätigt werden.

Unterlagen

Philipp Gubisch

Zahlungsoptionen

Vorkasse

Asset-Finanzierung